eOrganic authors:

Dr. Andrew T. Corbin Ph.D., Washington State University

Dr. Carol A. Miles Ph.D., Washington State University

Jeremy Cowan, Washington State University

Dr. Douglas G. Hayes Ph.D., University of Tennessee

Dr. Jennifer Moore-Kucera Ph.D., Texas Tech University

Dr. Debra A. Inglis Ph.D., Washington State University

Introduction

Certified organic farmers are currently allowed to use conventional polyethylene mulch, provided it is removed from the field at the end of the growing or harvest season. To some, such use represents a contradiction between the resource conservation goals of sustainable, organic agriculture and the waste generated from the use of polyethylene mulch. One possible solution is to use biodegradable plastic as mulch, which could present an alternative to polyethylene in reducing non-recyclable waste and decreasing the environmental pollution associated with it. This article explains how biodegradable plastic mulches are made; how biodegradability is measured; current techniques on evaluating biodegradable mulches; and research and policy progress to date. The purpose is to inform agricultural professionals, farmers, and policy makers about the suitability of biodegradable plastic mulches for use in certified organic agriculture. A glossary is provided at the end of this publication which includes definitions and terms commonly used when describing biodegradable plastic mulch. Terms included in the glossary are in bold text.

Plastic mulch films in agriculture

Polyethylene plastic mulch is widely used for crop production in the U.S. and worldwide, because it controls weeds, conserves soil moisture, increases soil temperature, improves crop yield and quality, has a relatively low cost, and is readily available (Schonbeck and Evanylo, 1998; Corbin et al., 2009; Miles et al., 2012). However, the sustainability of producing crops through the use of polyethylene mulch has been called into question because polyethylene mulch is made of non-renewable, petroleum-based feedstock, is generally only used for one growing season, and cannot be recycled in most regions. Recycling is limited because the mulch may be contaminated with soil and agrochemicals, specialized baling equipment is required before hauling, and facilities for recycling are often a long distance away. (Garthe and Kowal, 1993).

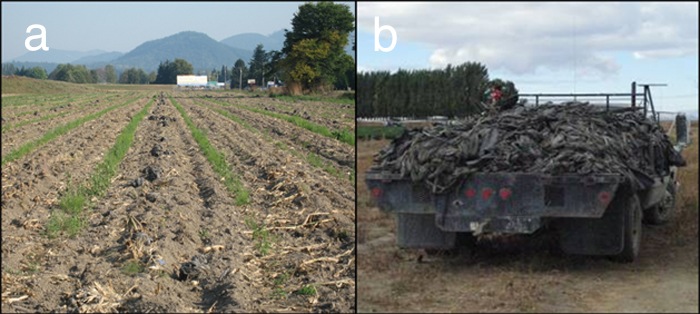

The high volume of waste generated by polyethylene mulches both in the field and in landfills raises many concerns (Figure 1). For example, in 2004 in the U.S., 143,000 tons of plastic mulch were disposed. While much of this waste entered the landfill at a cost to growers of up to $100 per acre, some was burned on site (Shogren and Hochmuth, 2004). Burning of polyethylene mulch can have undesirable environmental impacts, such as the release of dioxins as an airborne pollutant (Levitan, 2005; Lemieux, 1997). While there are no federal regulations restricting the open burning of plastics, the practice is banned in several states or counties in the U.S. (EPA, 2011; OAR, 2013). Utilization of polyethylene mulch by soil microorganisms in landfills is negligible, with the microbial conversion and abiotic oxidation products possibly consisting of environmentally harmful chemicals such as aldehydes and ketones (Hakkarainen and Albertsson, 2004). The use of biodegradable mulches could save significant labor and disposal costs, conserve resources, and decrease pollution (Smith et al., 2008).

Figure 1. (a) Typical post-season polyethylene plastic mulch waste in the field. (b) Ready for transport to the landfill. Photo Credit: C. Miles, Washington State University. From Corbin et al., 2013.

For these reasons, both new and experimental mulches that are designed to biodegrade (mineralize) fully into carbon dioxide and water, have been developed by industry and academic institutes over the past 25 years. To be a viable alternative in organic crop production, biodegradable plastic mulch must perform comparably to polyethylene mulch, especially in regard to durability and the ability to block light to prevent weed germination. Ideally, once the biodegradable mulch’s useful service life has ended, it is plowed into the soil where it should degrade. In the short-term, the mulch should lose mechanical strength and undergo a reduction in the degree of polymerization (Figure 2), or depolymerization, thereby making the polymer molecules accessible to microorganisms. Ultimately, the mulch should undergo at least 90% mineralization within a two-year period.

Figure 2. (a) Starch-based biodegradable plastic mulch (BioAgri®) in experimental field plots during harvest, 135 days after laying mulch. (b) 9 months post-harvest on soil surface, 348 days after laying mulch. (c) 9 months post-incorporation, 348 days after laying mulch. Photo Credits: J. Cowan (2a) and C. Miles (2a, 2b), Washington State University. From Corbin et al., 2013.

How are biodegradable plastic mulches produced?

Many biodegradable plastic mulches that are commercially available are films made from plant starch; these are prepared using conventional plastics processing technology. However, due to the poor mechanical properties of starch, including its brittleness, starch must be blended with other polymers and/or plasticizers. Products currently on the market that contain plant starch include Biomax TPS (DuPont, USA), Biopar (Biop, Germany), Paragon (Avebe, Netherlands), BiosafeTM (Xinfu Pharmaceutical Co., China), Eastar BioTM (Novamont, Italy), Eco-Flex® (BASF, Germany), Ingeo® (NatureWorks, USA) and Mater-Bi® (Novamont, Italy) (Hayes et al., 2012).

Two polymers that may have a future role in biodegradable plastic mulches are polylactic acid (PLA) and polyhydroxyalkanoate (PHA). PLA is a highly versatile, biodegradable polyester derived from 100% renewable resources such as corn and sugar beet starch, and offers great promise in a wide range of commodity applications (Drumright et al., 2000). Starch is converted by microorganisms into lactic acid through fermentation. Lactic acid molecules are then linked together into long chains called polymers. PLA is a relatively inexpensive biopolymer to manufacture (~ $0.95 per lb), and can be produced in large quantities (Endres and Siebert-Raths, 2011). The PLA polymer is highly attractive for biological and medical applications because it can be spun into filaments that can be used to make textiles or films (Gupta et al., 2007). PHAs are promising biodegradable plastics that have been highlighted as “green” polymers because they are made from renewable resources in a one-step process by the bacterial fermentation of sugars and/or lipids (Kaihara et al., 2005; Posada et al., 2011; Hayes et al., 2012). PHA polymers may be produced from microbes or plants; but currently, microbes are the primary source (Keshavarz and Roy, 2010).

New experimental agricultural mulches have been prepared from PLA and PHA blends using nonwovens textile technology (Wadsworth et al., in press). Nonwovens are manufactured sheets, webs or bats (wadded rolls) of directionally or randomly oriented fibers or filaments, bonded together. Nonwovens may be manufactured by spunbond or meltblown processes. In the spunbond process, polymers are first melted and then extruded through spinnerets, producing filaments which are cooled and laid down on a conveyer belt to form a web. In the meltblown process, polymers are extruded through a die or spinneret, and the filaments are stretched, dispersed, cooled, and then collected on a roll. Generally, meltblown nonwovens have smaller fiber sizes and have lower mechanical strength than spunbond nonwovens (Hayes et al., 2012).

Some processes that are used to form biodegradable polymers utilize additives, such as nucleating agents (chemical substances incorporated in plastics for the growth of crystals in the polymer melt), plasticizers, coloring agents, performance additives, and/or lubricants to improve the mechanical properties of the plastic. The environmental impact of many additives may be a major concern in organic as well as conventional crop production. Some additives are derived from petroleum and/or are chemically processed, and are therefore considered synthetic material by National Organic Program (NOP) standards (Hayes et al., 2012; NOS, 2012), which has prevented their use in U.S. organic agriculture. In addition, the NOP considers PLA to be synthetic because PLA is chemically polymerized (Briassoulis and Dejean, 2010). While the PHA polymer is made directly by microorganisms in the fermentation process (thereby considered “natural” by the NOP), it is highly crystalline, making its end product more brittle, and less desirable, unless blended with PLA or other co-polymers (Hayes et al., 2012).

What constitutes biodegradability?

Many agricultural plastics are advertised as “biodegradable”; however, such claims need to be evaluated carefully. For a manufacturer to employ the claim of biodegradability, a set of specified standards need to be met. ASTM International (formerly known as the American Society for Testing and Materials) has prepared a series of standards for “compostable plastics” to measure biodegradability under municipal or industrial composting conditions, referred to as ASTM D6400.

The ASTM D6400 specification encompasses several ASTM standardized tests, such as the “inherent biodegradability” of the plastic material via ASTM D5988-03. This test measures the microbial conversion of the plastic’s carbon (C) atoms to carbon dioxide (CO2), over time. A standard that is embedded in ASTM D6400 specifies that 90% of C atoms must be mineralized, that is, converted to CO2 within 180 days by microorganisms (ASTM, 2003). In the laboratory, CO2 release is measured through a relatively inexpensive titration method.

Biodegradability-related standards are comprised of criteria that address the following three issues:

(i) The conditions of the system —industrial-scale composting or anaerobic digestion, soil, marine, etc.

(ii) The time frame—number of days for carbon molecules in plastic to be converted to CO2.

(iii) The fraction of carbon atoms that are to be fully mineralized by microorganisms – generally expected to be at least 90%.

Many mulches claiming to be “biodegradable” are actually “compostable”, i.e., able to fulfill the requirements of ASTM D6400, or related standards. Moreover, no standard currently exists for measuring the biodegradability of plastics incorporated into soil under field conditions. To meet this need for measuring biodegradability within the soil, ASTM International is developing a new standard (Work Item 29802) entitled Aerobically Biodegradable Plastics in the Soil Environment (ASTM, 2012). In this new standard, biodegradable mulches must break down into CO2, water and environmentally benign substances within one or two years, leaving no harmful residues. The ability of existing and emerging biodegradable plastic mulch films to meet these criteria in the soil environment has been the topic of several investigations (Harding et al., 2007; Hayes et al., 2012; Miles et al., 2012; Hoshino et al., 2007; Kapanen et al., 2008; Kijchavengkul et al., 2008; Kyrikou and Briassoulis, 2007; Mohee and Unmar, 2007; Tachibana et al., 2009; Wadsworth et al., 2009), and continues to be researched.

Evaluating degradation/deterioration vs. biodegradation

The term degradation is used to denote changes in physical properties caused by chemical reactions involving bond scission in the macromolecule (polymer). Biopolymer degradation includes changes of physical properties, caused not only by chemical reactions, but also by physical forces. Because the term polymer degradation involves a deterioration in the functionality of polymeric materials, “degradation” and “deterioration” are often used interchangeably (Schnabel, 1992). ASTM and the International Organization for Standardization (ISO) define degradation as an irreversible process leading to a significant change of the structure of a material, typically characterized by a loss of properties (e.g. integrity, molecular weight, structure or mechanical strength) and/or fragmentation, as affected by environmental conditions, proceeding over a period of time, and comprising one or more steps (Krzan et al., 2006).

The efficiency of the plastic degradation process varies by environment and may also be affected by the concentration of chemicals present that may react with the plastic. Environmental factors such as temperature, moisture level, atmospheric pressure, concentrations of acids and metals, and light exposure all have an effect on the rate of degradation that is due to microorganisms i.e., biodegradation (Kyrikou and Briassoulis, 2007). However, weight loss and other physical, chemical and mechanical property reductions in biodegradable plastic do not comprise the full measure of percent biodegradation unless microbial utilization of C (via CO2 conversion) is also measured. Percent biodegradation is the measure of the rate and amount of CO2 released from the total C input (from the mulch), and is a direct measure of the amount of C being utilized by the microbial community (Narayan, 2010).

While biodegradation measurements in the field or laboratory are relatively straightforward for well equipped and trained scientists, they are impractical for farmers to perform. Until the scientific community and the NOP can provide farmers with repeatable results on field performance of biodegradable plastic mulch products that are recommended for organic use, it may be advisable for farmers to monitor the degree of mulch degradability (see limitations below). Miles and others (2012) assessed percent visual deterioration (PVD) of biodegradable plastic mulch under field conditions and counted the number of rips, tears and holes (RTH) in a designated portion of the mulch twice per month. PVD proved to be a fair assessment of mulch deterioration while RTH did not. Cowan (personal communication) evaluated PVD during two late-summer broccoli seasons, and then measured mulch fragment recovery over the course of one year after mulches were tilled into the soil. At each of five sampling times, three random four-inch-diameter x six-inch-deep soil samples were collected (using a golf cup cutter) per 28-foot of mulch treated bed. Samples were sieved to retrieve mulch fragments,and photographs of mulch fragments were digitally analyzed to measure average area of individual fragments, fragment counts, and total fragment area. Findings indicated that post-tillage mulch recovery can be measured using this method. Two of the mulch products evaluated, Crown 1 and BioAgri, were recovered at 0% and 34%, respectively, within 13 months after soil incorporation.

Moore-Kucera et al., (in prep.) as part of a three-year field study, buried mesh bags containing a 4 inch square of biodegradable plastic mulch (previously weathered in the field for one growing season) and 300-400 grams of native agricultural soil four inches deep in field plots at three locations (Knoxville, TN, Lubbock, TX, and Mount Vernon, WA). At each location, one mesh bag was removed from replicated plots every 6 months for 24 months and the residual mulch pieces were evaluated for percent surface area remaining (Figure 3). Results varied widely by location, each with unique physical (light, temperature, moisture, wind, etc.), chemical (pH) and soil microbial attributes (Corbin et al., 2013; Bailes et al., in press; Moore-Kucera, 2012). For further information on experimental mulch degradation in the field, see the Washington State University Factsheet Using Biodegradable Plastics as Agricultural Mulches (Corbin et al., 2013). Although these types of field measurements will not determine percent mulch biodegradation per se, they are relatively simple sampling procedures that farmers, Extension or Agricultural Agency personnel can perform without the use of laboratory equipment, and provide a visual estimate of degradation/deterioration and mulch recovery in the field.

Figure 3. Samples of starch-based biodegradable plastic mulch (BioTELO®) recovered after twenty-four months burial in the field at three experimental locations. Photo credit: J. Moore-Kucera, Texas Tech University.

Biodegradable plastic mulch limitations in certified organic production

In the U.S., organic crop producers have not been able to use currently available biodegradable plastic mulch products because these products did not conform to NOP standards. To be acceptable for organic production, biodegradable plastic mulch must be entirely composed of constituents derived from natural resources (bio-based), cannot contain synthetics such as petroleum-derived ingredients or additives, and cannot be chemically modified during the manufacturing process (NOS, 2012; Corbin et al., 2013; Corbin et al., 2009).

An additional requirement to meet the organic standards is that feedstocks, such as corn, used to produce the polymer, must be free of genetically modified organisms (GMOs). Similarly, any polymer made from microbial fermentation, such as PHA, must be produced by organisms that have not been genetically modified. Biodegradable plastic mulch manufacturers must certify that their feedstocks and microbial fermentation processes are GMO-free; however, there is no available test to verify GMO byproducts in the final product. While there is no specific NOP policy on GMOs in biodegradable plastic feedstock, the NOP has developed an ad-hoc committee to clarify the GMO issue.

Another requirement for use in certified organic production is that the resins and any inert additives used in the processing and formulation of biodegradable plastic mulch products must be identified and compared to the National List of allowable substances. The designation of ingredients as “proprietary” is not adequate for review and approval by the National Organic Standards Board (NOSB) – the sole authority to recommend adding or removing materials from the National List of acceptable and prohibited substances.

Finally, any biodegradable plastic mulch that may eventually be approved for use by the NOP must completely biodegrade into carbon dioxide, water, and microbial biomass within a “reasonable” timeframe without forming harmful residues or by-products. Sufficient data will be needed to verify that each biodegradable mulch is truly biodegradable in an agricultural system.

A growing contingency of manufacturers and organic farmers who wanted this interpretation of the NOP standards to be revised so that biodegradable plastic mulches are included on the National List of allowable “synthetic” substances has recently gained recognition (NOSB, 2012). As a precedent, the organic standards in Canada and the European Union (E.U.) have allowed some use of currently available biodegradable plastic mulches. In 2012, the Biodegradable Products Institute (BPI) petitioned the NOP to allow the addition of biodegradable plastic mulch under section 205.206 (c) of the National Organic Standards Biodegradable Plastic Mulch Made from Bioplastics: without removal at the end of the growing or harvest season (BPI, 2012). In October 2012, the NOSB voted 12-3 to formally recommend the NOP approve biodegradable plastic mulch in organic production (NOSB, 2012). Included in this recommendation is a requirement that organi

Read more here:: Current and Future Prospects For Biodegradable Plastic Mulch in Certified Organic Production Systems